ADVANCE8D (ECU ONLY)

The Advance8D gives diesel engines the torque and power they claim with furious accelerations provided by an amazing speed of calculation, in safety. From 1 to 6-cylinder, common rail or pump injectors. It allows several tunings (selectable by rotator) thanks to its multimapping functions. Evolved strategies of control allow an effective protection of the engine.

Advance8D is the must tool for the diesel racing management engines.

This racing management is incommensurate with tinkering settings on the chip of a series ECU mainly made originally for emission control.

Thanks to its two high performance microprocessors and its multiple possibilities, Advance8D will allow the engine to get the torque and the power which it claims, with furious accelerations provided by an astonishing speed and power of calculation, in the safety.

Several tunings can get along for the same engine, from the dragster (very high performance sprint running but very trying for the mechanics) until rally raid (performance in the mechanical safety with watched consumption), through circuit and road rally.

The desired tuning can be selected while running, by a rotator or a dashboard switch, allowing a super boost of the engine if necessary.

TECHNICAL PRESENTATION

CONFIGURATION

• 8 injection channels

• 25 fully programmable auxiliary outputs including two Peak and Hold outputs

• 1 RPM sensor selectable Hall effect or inductive on crankshaft flywheel

• 1 Main phase sensor selectable Hall effect or inductive on camshaft flywheel

• 1 internal power supply tension measurement

• 4 logical input type on-off switch

• 6 resistive inputs NTC-PTC-PT200 or logical

• 8 analogic 0-5 volts inputs

• 10 selectionnable analogic-resistive inputs

• 2 knock sensors inputs with differential measurement

• 4 SENT or PWM or frequency inputs

• 4 speed inputs Hall effect or magneto resistive, number of teeth from 1 to 128

• 16 CAN-Bus inputs (for example switches or rotators provided by the dashboard)

COMMON RAIL INJECTION

See the kits Common rail piezo and inductive.

Very advanced engine management functions allow a total optimization of the engine operation:

• Dynamically adjustable number of injections by engine cycle: Pilot 2 – Pilot 1 – Main – Post 2 (optional) – Post 1

• Injections phases adjustable injection by injection

• Dynamic control of distance between injections of the same cylinder

• Injection covering allowed between cylinders

• Injection correction cylindre by cylinder

• Specific racing management of particles filters (if DPF present)

• Correction of richness by wideband Lambda sensor

PUMP INJECTORS INJECTION

See the kit pump injectors.

HELP IN THE SETTING

For a fast tuning, the maps of engine start and rise in temperature are preset.

The PID of devices commands (fuel pressure, turbo, …) are also preset.

ADVANCED FUNCTIONS OF TURBO MANAGEMENT

The turbo management is made by the PWM command of a pneumatic electrovalve of leak or a variable geometry. Wastegates with back pressure are also managed.

• 1 turbo

• 2 twin turbos in parallel (1 by bank of cylinders)

• 2 sequential turbos in parallel

• 2 staged sequential turbos

• 3 turbos, with two in parallel and the third serial with both first ones

Turbos in sequential mode are started only under selectable conditions.

Turbo management in pressure or in turbo rpm or both with dynamic choice of the type of management.

For ‘V’ engines with intake separated by bank, it is possible to read 2 pressure sensors, each allocated to a bank of cylinder, to manage each of the twin turbos with its own pressure.

• Turbos protection by limitation of turbo rpm (takes into account the altimetric pressure)

• Pressure and turbo rpm target tunable according to gear position, exhaust or intake or engine temperature, altimetric pressure

ADVANCED FUNCTIONS OF FUEL PRESSURE MANAGEMENT

It can control 1 or 2 high pressure pumps (in tunable peak and hold) either separately, or one being the slave of the other. In that case, the 2nd pump is only activated when the needed fuel quantity reaches the maximum possible that the 1st one can deliver.

The rail leak control is a Peak and Hold command in PWM.

The fuel high pressure pump control is also a Peak and Hold command and can be done in two ways:

In PWM by the fuel flow supplying the pump, the frequency and direction control are adjustable.

In engine synchronous command with tuning of the number of came push per engine cycle and push phases (to follow the camshaft drift).

Whatever the type of command used, the RCO of the command is managed by a PID to follow the pressure target.

• Fuel high pressure management by the flow (high pressure pump supply side), by the rail leak or both

• Progressive rise in pressure at the engine start

• Procedure of cold fuel heating

ADVANCED FUNCTIONS OF RPM LIMITER

• Rpm limiter by injected quantity decrease (PID)

• Launch limiter and race limiter, with launch limiter deselection by dashboard switch for road driving

• Modifiable rpm limiter following gear position, intake temperature or engine temperature or elapsed time in limiter

ADVANCED FUNCTIONS OF GLOW PLUG MANAGEMENT

• PWM management of push tension for the low voltage fast plugs

ADVANCED FUNCTIONS OF GEARBOX MANAGEMENT

Sequential gearbox management or specific management of robotized gearbox.

• Logical or analog switch with definition of the triggering thresholds

• The order of gears can be automotive type or special

• Different time of intervention at upshift and downshift

• Intervention time in function of gear position, rpm and engine torque

• Intervention at gear shifting by injection cutoff and/or modification

• Anti jolts procedure (transmissions protection) at gear shifting

• Programmable engine re acceleration at downshift (blip)

ADVANCED FUNCTIONS OF ENGINE PROTECTION

• Programmable reaction (by limitation of torque, rpm, or engine cutoff) on problem of oil pressure, fuel pressure, engine and intake and oil and exhaust temperature, turbo pressure, with alarm lights and recording of the defects

ADVANCED VEHICLE MANAGEMENT

• Cruise control

• Traction control

• Vehicle speed limitation (rallye raid, pitlane, …)

ADVANCED ENGINE MEASUREMENTS

• Every measure has a customizable digital filtering

• Every measure maybe assigned in a selectable way to a physical input of the ECU, to a calculated value (ie double potentiometers), or to a CAN-BUS sensor

• For every measure of the ECU, it is possible to define a strategy of detection of failure, a strategy of replacement value in case of failure, or to use the standard strategies supplied by the ECU

• Turbo speed, wheels speed

• Wideband Lambda sensor

• Oil pressure, fuel pressure, oil t°

• Exhaust temperature by thermocouple module or PT200

ADVANCED PROGRAMMABLE STRATEGIES

Extremely flexible and simply programmable strategies allow the motorist to multiply the possibilities of tuning

The use of these advanced functions and the development of specific strategies does not require either the learning or the knowledge of a programming language. The innovative and natural technique, called SKYMCOD Mapped programming, developed by Skynam, performs this role.

For example,

• Several selectable possible engine tuning by rotator or by quite other condition chosen by the motorist (for example multi fuels with programmable switching, additives)

• Addition of engine devices (intake flaps, exhaust throttle)

• Programmable auxiliary inputs for new measurements creation

• Management of restrictor pressure for supercharged engines

• Programmable water injection

• The ECU can react to the oil temperature or to the oil pressure according to the rpm or to quite other parameter or the combination wished to control, activating alarms or switching off the engine, or changing the strategies of injection, overboost, or other

• The motorist can intercept all the targets of the ECU (injection, turbo pressure, fuel high pressure, richness correction, rpm limiter) and modify them with his appropriate strategies

AUXILIARY CAN-BUS

Three completely programmable auxiliary CAN-BUSes (11 and 29 bit identifiers, speed until 1 Mbits) allow to exchange data with the others connected nodes, car manufacturer devices or data recording or dashboard. The received data can be used in the advanced functions of calculations and developments of strategies.

AUXILIARY OUTPUTS

25 completely programmable auxiliary outputs.

They can be configured in On-Off (programmable hysteresis), PWM from 10 to 10000 Hz or angular or engine synchronous phased commands, with adjustable cyclical ratio (and phase), and controled by any combination of parameters known by the ECU, including the values received from the auxiliary CAN-BUSes, and or from the sophisticated strategies developed by the motorist and fully configurable PIDs.

Two of these auxiliary outputs are in Peak and Hold command. This type of command allows a better management of devices with high current command, such as fuel high pressure pumps and rail leak solenoids for common rail injection.

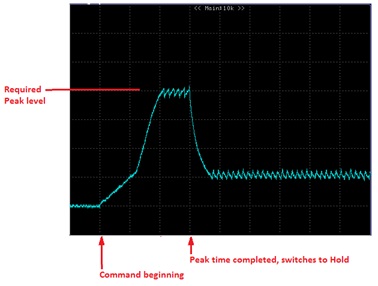

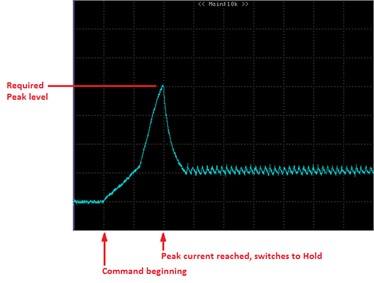

The Peak and Hold command is composed of two parts, during which the voltage is supplied by the engine 12 volts battery supply with current control by switching the battery power:

The Peak delivers a strong current for a few hundred microseconds. This peak is a necessary part for a very fast opening of the solenoid valve. Two peak command types are allowed:

1) The ECU controls the current during all the Peak time then switches to the Hold.

2) The ECU switches to the Hold as soon as the Peak current is reached. The Peak time is the maximum duration before the command switches to Hold, in the case where the desired current is not reached (for example if the battery tension is too low).

In both cases, the Hold maintains the opening of the solenoid valve without damaging it by an excessive rise of its coil temperature (lower level of current).