New software version Chal5_ENU-2.7.0.0.zip of the Challenger5 ECU

SECURE METHOD OF ECU UPGRADE

Here is the simple and secure method of update of your ECU with a new software version.

WARNING LEVEL : NORMAL

NEW FEATURES AND IMPROVEMENTS

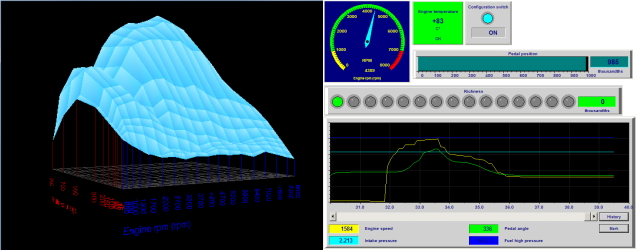

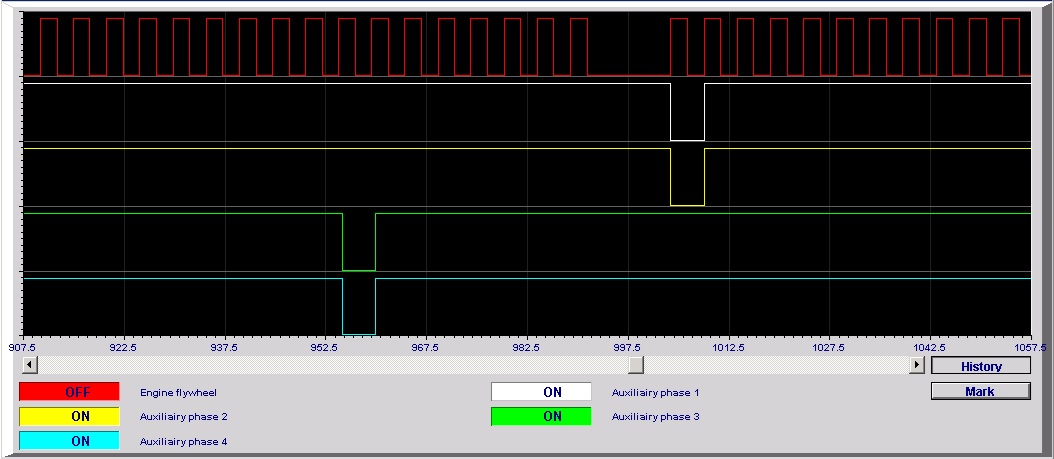

Display scope of flywheel and phase teeth

• Allows an easy test of flywheel teeth for engine synchronization.

See new document ‘Challenger5 Engine flywheel and phases test – V100’

Engine protections

• Programmable reaction (by limitation of torque or engine cutoff) on problem of engine temperature, intake temperature, turbo pressure, … with alarm lights and recording of the faults.

See new document ‘Challenger6 Engine protections – V100’.

Possibility of using Innovate wideband Lambda modules

• but these must be programmed specifically to be adapted to Sybele ECUs.

See new document ‘Challenger5 Use of the Lambda sensor – V130’.

The document ‘Use of the Lambda sensor’ provided by the Challenger5 ECU installation must be V130. Version V120 gave incorrect information on the programming of the Innovate modules. Version V130 corrects these errors. But you can also download the CORRECTIVE DOCUMENT by clicking here.

CONTENT

Challenger5 Tunewares:

• System V240 (new – 3rd 03/2024)

• Throttle/RPM: V270 (new – 3rd 03/2024)

• Pressure/RPM and turbo: V270 (new – 3rd 03/2024)

Documentations in English:

• Challenger5 tuning software pack: 22 separate documents, each for one specific fonction of the ECU, with many didactic examples (new – 3rd 03/2024)

• Complete tuning of Hard cut rpm limiter document (24th 05/2022)

• Challenger5 installation: V1.30 – with commands of ignition modules (new – 26th 10/2023)

• Challenger5 options installation: V1.20 – sequential gearboxes, air electrovalves, … (08th 09/2021)

Note:

• Does not contain Winjall software. Winjall must first be downloaded and installed apart.

• Does not containt the sensors convertion maps nor the actuators command maps. These maps have to be downloaded and installed apart with the pack SensAct.

LAST SECURITY CRITICAL MODIFICATION DONE

Not needed.

NEEDING Winjall V9.9.0.0 (see specific downloading)

V9.9.0.0 or later version of Winjall software must mandatory have been installed first.

HOW TO UPGRADE TUNEWARES

• Download new .zip Challenger5 software pack file and save it in a directory on your hard disk.

• If you have already installed a former version of this pack, you have to usinstall it before installing this new one:

In Windows XP, execute ‘Start/Parameters/Configuration/Add-Remove programs’.

In Windows 7 and latter versions, execute ‘Start/Parameters/Configuration/Programs and features’.

In the software list, select Challenger5 then ‘Uninstall’. Follow uninstall instructions.

• With the files explorer, double click on the downloaded software pack .zip file, then double click on Setup. At the question on files extraction, answer ‘Extract All’.

• If the installation does not automatically start: in the new directory created by the extraction, double click on Setup (application).

VERSIONS HISTORY

(Improvements are added from a version to the next one)

Throttle/RPM : V260 (System V230)

Pressure/RPM : V260 (System V230)

1) Possibility of using Innovate wideband Lambda modules but these must be programmed specifically to be adapted to Sybele ECUs.

Throttle/RPM : V250 (System V230)

Pressure/RPM : V250 (System V230)

1) Hard cut limiter: Machine gun Hard cut RPM limiter with burst of flames.

Throttle/RPM : V240 (System V230)

Pressure/RPM : V240 (System V230)

1) Intake pressure filtering adjustment:

– This filtering removes pressure instabilities in the intake manifold.

– The intake pressure filtering adjustment is accessible even without a professional license.

– See the document ‘Pressure/rpm Atmo Turbo and bang-bang’ which gives a very detailed explanation of how to filter (averaging) the intake pressure to avoid instabilities and what the problems are if this is not done correctly.

2) Dynamic advance at tick over:

– Dynamic advance limit memorization.

3) Improved engine starting:

– Added corrections at engine start and engine temperature of the intake air solenoid valve position.

4) Improved coil loading time:

– Coil loading times accept up to 15000 µs and no longer vary when we return to their calibration.

5) Improved injection and ignition display:

– Real-time display of the corrections made on the advance and injection time by engine t °, intake t °, atmospheric pressure.

Throttle/RPM : V230 (System V220)

Pressure/RPM : V230 (System V220)

1) Improvement of sequential gearbox management:

– Optimization of the gear upshift time (faster upshifting).

– Ignition cutoff at gear downshift (faster downshifting on strong brakings of the vehicle).

– Possibility to select the old way of shifting on slower or less precise gearboxes.

– The ECU agrees to intervene on the engine even if the gear position measurement is in error.

Read carefully new documentation for sequential gearboxes.

Throttle/RPM : V220 (System V210)

Pressure/RPM : V220 (System V210)

1) Improvement of sequential gearbox management:

– A programmable ignition cutoff was already allowed on gear upshift.

– A programmable ignition cutoff has been added on gear downshift, facilitating the gears shifting during difficult conditions.

2) Auxiliary CAN-Bus management:

– Addition of two functions of simplified frames transmission toward the Sybele compatible dashboards.

These functions allow a better confidenciality of the ECU tuning.

Throttle/RPM : V210 (System V210)

Pressure/RPM : V210 (System V210)

1) Significant improvement of of engine startup security:

– In the previous versions, during difficult conditions of engine start-up, the microprocessor could lose the capacity to perform its measurements (throttle, pressures, temperatures, …), causing an engine stalling.

– This version prevents the loss of the measurements even in case of battery tension drop down at the engine start.

Throttle/RPM : V200 (System V200)

Pressure/RPM : V200 (System V200)

1) Improvement of quality and robustness of the injection command:

– When engine speed instabilities of a sufficient level (due to vibrations or else) happened, the previous versions may lose one or more injections, up to making thinking to a small limiter.

– This new version never loses any injection (nor ignition) whichever is the engine operation.

2) Use of wide band Labda sensors:

– Improvement of the reliability of the injection time self learning at high richness.

– Better detection of Lambda sensor failure.

3) Renault Clio RS flywheel:

– In addition to the flywheels with one or two missing teeth, or one supplementary tooth, it is now possible to directly operate with the Clio RS flywheels.

Throttle/RPM : V150 (System V130)

Pressure/RPM : V150 (System V130)

1) New function to test injection and ignition commands without running engine:

Allows to easily test the installation or the system operation.

2) Improvement of the resynchronization in case of rpm sensor signal loss:

If for some reason the synchronization of the ECU is lost due to a rpm sensor signal loss, the ECU re-synchronizes much faster on the engine cycle.

3) Significant acceleration of richness correction recovery on re-synchronization on exit of rpm sensor signal loss:

When the synchronization of the ECU is lost due to a rpm sensor signal loss, the injection and ignition is stopped, and the richness correction is also stopped. At the ECU re-synchronization, the richness correction recovery (if richness correction is enabled) is very faster.

4) Powershift strain gauge switch:

More and more gearboxes are equipped with a strain gauge switch, and no more with a On-Off switch.

This version makes much more easier the tuning of this kind of switches.

Throttle/RPM : V140 (System V120)

Pressure/RPM : V140 (System V120)

1) Very efficient improvement of launch procedure (see new limiter documentation):

To avoid the skating at the vehicle take-off, rather than going up suddenly from the launch to the race limiter, the rpm limiter is gradually raised from the launch limiter to the race limiter, at the maximum speed at which you allow the engine to rev up (tunable).

2) Traction control (see new traction control documentation):

Traction control helps prevent spinning of the drive wheels, which occurs most often when the torque at the wheel is important and/or wheel grip is too low.To avoid the losses of grip the ECU has been equipped with a traction control by monitoring the engine acceleration in fonction of gear position.

3) New CAN-Bus protocol added to command stand alone displays (see new auxiliary CAN-Bus documentation):

It sends some frames containing the main data of the engine, in a simple form, and it is easy to get these data with a data recording or with stand-alone displays such as for example the small and cheap THQTronic displays that allow to display at your choice one or the other engine measurements, such as the gear position, engine rpm, the throttle position, the intake pressure, …

Throttle/RPM : V130 (System V120)

Pressure/RPM : V130 (System V120)

This version must not be used. It has a BUG on the injection command and the injection time cannot be tuned.

It is replaced by the version V140.

Throttle/RPM : V120 (System V110)

Pressure/RPM : V120 (System V110)

1) Allows Challenger5 ECU to also manage turbocharged engines with and without bang-bang.

2) Multimapping richness tuning:

– Modification of richness target by multiplicative coefficient in place of absolute quantity.

– When importating in a new Tuneware the data of a previous version one, the old absolute target correction is not imported. This will require to manually correct the new richness modification by copying the coefficients of injection map modification.

3) Exceedings recording:

– Error fixed on delayed lighting of the exceeding signal LED (the LED was not switched on).

4) Auxiliary outputs:

– Fixed error on fixed ground output mode (the output did not give the ground).

– Fixed error on advanced display mode (advanced mode was displayed even if not required on real machines – not generic).

Throttle/RPM : V110 (System V110)

Version 110 is the base version of the new Challenger5 ECUs, only for atmospheric engines.

Throttle/RPM : V100 (System V100)

Version 100 is an obsolete version not usable with Challenger5 ECUs.