New software version Chal4_ENU-6.4.0.0.zip of the CHALLENGER44+ ECU

THIS VERSION MUST MANDATORY BE LOADED IN THE ECU: IT PREVENTS THE POSSIBLE LOSS OF THE CHALLENGER4+ DATA (See below security critical modification)

SECURE METHOD OF ECU UPGRADE

Here is the simple and secure method of update of your ECU with a new software version.

WARNING LEVEL: SPRCIAL

THIS VERSION MUST MANDATORY BE LOADED IN THE ECU: IT PREVENTS THE POSSIBLE LOSS OF THE CHALLENGER4+ DATA (See below security critical modification)

NEW FEATURES AND IMPROVEMENTS

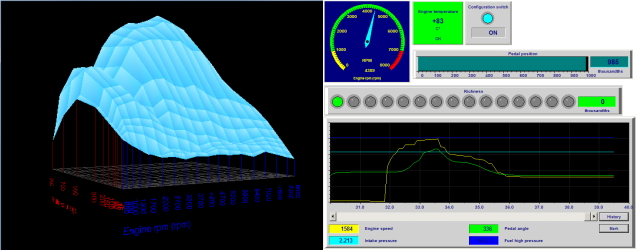

1) Allows 3D maps display.

2) Throttle position filtering modified for better stability.

CONTENT

Challenger4 Tunewares:

• System V610

• Throttle/RPM: V640 with system V610 (new – 28th 08/2011)

• Pressure/RPM and turbo: V640 with system V610 (new – 28th 08/2011)

• Archives of all the former Tunewares to open the not yet updated machines of this type

Documentations in English:

• Challenger4 tuning software pack: 18 documents, each one deals with a functionality of the Challenger4, deeply with explicative examples (30th 10/2008)

• Challenger4+ installation: V1.30 – ignition modules management (26th 06/2008)

• Challenger4+ options installation: V1.20 – sequential gearboxes, motorised throttles, air electrovalves, bang-bang, … (27th 08/2007)

Note:

• Does not contain Winjall software. Winjall must first be downloaded and installed apart.

• Does not contain the sensors convertion maps nor the actuators command maps. These maps have to be downloaded and installed apart with the pack SensAct.

SECURITY CRITICAL MODIFICATION PERFORMED

On versions Throttle/rpm and Pressure/rpm prior to V640 and the system versions prior to V610

During the engine starting under cranking, or if we forget to switch off the 12 volts after key during a long time, if the battery tension drops below 6 volts (weak or damaged battey or low charge), the ECU could lose all the engine tuning data.

From Throttle/rpm and Pressure/rpm versions V640 and system version V610

The data loss of the ECU does not exist anymore

OPERATION CRITICAL MODIFICATION PERFORMED

Since the V500 system version and so on this new version:

It is mandatory to execute again the Top Dead Center Mark calibration

• on changing from Hall effect RPM or phase sensor to an inductive one, or vice versa.

• on importing a tuning from a version older than V500 using an Hall effet RPM or phase sensor

To avoid engine breaks by TDCM calibration oversight on Hall effect sensors, Winjall does not import Hall sensor type when updating new Tunewares (since V500) with old Tunewares (former than V500).

In this case, the sensors remains on the inductive type, and the engine will not start if it owns one or two Hall effect sensors.

You then have to execute ‘Sensor type’ calibration to set by hand the Hall type, and a warning message with a dead head display remembers you that the TDCM calibration is to change.

NEEDING Winjall V9.9.0.0 (see specific downloading)

V9.9.0.0 or later version of Winjall software must mandatory have been installed first.

HOW TO UPGRADE TUNEWARES

• Download new .zip Challenger4+ software pack file and save it in a directory on your hard disk.

• If you have already installed a former version of this pack, you have to usinstall it before installing this new one:

In Windows XP, execute ‘Start/Parameters/Configuration/Add-Remove programs’.

In Windows 7 and latter versions, execute ‘Start/Parameters/Configuration/Programs and features’.

In the software list, select Challenger4+ then ‘Uninstall’. Follow uninstall instructions.

• With the files explorer, double click on the downloaded software pack .zip file, then double click on Setup. At the question on files extraction, answer ‘Extract All’.

• If the installation does not automatically start: in the new directory created by the extraction, double click on Setup (application).

VERSIONS HISTORY

(Improvements are added from a version to the next one)

Throttle/RPM : V630 (System V610)

Pressure/RPM : V630 (System V610)

1) Full resistant to memory lost on alimentation tension drops at the engine start.

2) Improvement of machine internal security and Tunewares security.

3) Error corrected in Winjall on calibrations functions locked when exit from Top Dead Center calibration with cancel button.

Throttle/RPM : V620 (System V601)

Pressure/RPM : V620 (System V601)

1) Allows a fast and easy tune of the turbo pressure loop control.

2) Allows getting the bang-bang from the tick over for canon ball move off.

Throttle/RPM : V610 (System V600)

Pressure/RPM : V610 (System V600)

Version 610 and 611 are identical for the Challenger4 ECU inside working (same Tunewares).

This 611 version allows in addition to 610 to use the new functionalities of Winjall 3.6.0.0 as the use of many generic machines (virtual ECUs) together for the copy/paste an Tuneware comparison operations without the need of an ECU physically connected to the PC (see Winjall specific downloading).

A) OPERATION IMPROVEMENT:

1) Allows to tune RPM hysteresis of RPM limiter.

2) Tuning of the Move On for pressure/RPM engines (supplementary throttle/RPM function accelerating pump).

Improvement of accelerations and tick over leaving.

3) Allows to define specific fault strategies in case of analog sensor disfunctioning.

See ‘Advanced operations’ in document ‘Challenger4 tuning software pack’.

4) Improvement of Lambda sensors faults detection.

5) Injection altimetric correction coefficient tuning.

Altimetric conditions adaptation on injection and ignition was already existing in Challenger4 ECUs, but was not tunable on former versions.

6) Dashboards CAN faults detection improvement.

Throttle/RPM : V600 (System V600)

Pressure/RPM : V600 (System V600)

A) CRITICAL MODIFICATION OF OPERATION:

Improvement of machine internal security.

B) OPERATION IMPROVEMENT:

1) Allows to define specific fault strategies in case of analog sensor disfunctionment.

2) Improvement of Lambda sensors faults detection.

3) Injection altimetric correction coefficient tuning.

4) Dashboards CAN faults detection improvement.

Throttle/RPM : V500 (System V500)

Pressure/RPM : V500 (System V500)

A) CRITICAL MODIFICATION OF OPERATION:

1) Critical modification on Hall effect RPM and phase sensors.

In Hall effect sensors, teeth reading edge are changed compared to old versions and needs to calibrate again TDC mark.

B) OPERATION IMPROVEMENT:

1) Turbo correction integral calculation has changed in Challenger4 since V500 version turbo Tuneware version to:

– increase precision of integral speed tuning

– avoid turbo pressure instabilities and oscillations.

The integral map effect has been divided by 256 inside the ECU:

– If you use the turbo integral tuning standard version provided by Skynam with software pack:

you don’t have to care about this modification.

– if a map of this type has been specially tuned for turbo Tuneware version former than V500, it should not be used as is for new Tunewares:

Each signed coefficient value in this old map should be multiply by 256 for finding the same tuning in the new Tuneware.

2) Motorised throttle correction integral calculation has changed in Challenger4 since V500 turbo and Throttle Tuneware versions to:

– increase precision of integral speed tuning

The integral map effect has been divided by 256 inside the ECU:

– If you use one of the motorised throttle integral standard tuning version provided by Skynam with software pack:

Simply load again the Skynam map corresponding to your motorised throttle with the ‘Read data file’ function.

– if a map of this type has been specially tuned for any Tuneware version former than V500, it should not be used as is for new Tunewares:

Each signed coefficient value in this old map should be multiply by 256 for finding the same tuning in the new Tuneware.

Throttle/RPM : V451

Pressure/RPM : V331

A) OPERATION IMPROVEMENT:

(see new document Challenger4 Tuning software pack)

1) Improved starting on hard to start engines with minimum Flywheel synchronisation test RPM calibration

On some engines with a very light flywheel (for exemple motorcycle engines) or with a very irregular cycle, high working irregularities can be found at very low RPM that can disturb the synchronisation on flywheel.

That gives very difficult startings: the engine coughs but does not start, because flywheel synchronisation test done by the ECU at each engine round fails.

The ECU then stops ignition and injection, synchronises again on flywheel, and runs again the engine starting.

This minimum flywheel synchronisation test RPM calibration allows to tell the ECU to not execute this test before to reach to a certain RPM.

This RPM is normally 0, and the test is done as soon as the engine runs.

For hard to start engines, the minimum RPM test should be set just above the RPM under starter.

Throttle/RPM : V450

Pressure/RPM : V330

A) NEW CHALLENGER4 FUNCTIONS:

(see new document Challenger4 Tuning software pack)

1) Pressure/RPM and Turbo: New management of ignition advance tuning map, in cut off and bang-bang (very efficient)

2) Pressure/RPM and Turbo: Improvement of accelerating pump calculation (needs an adaptation of the accelerating pump coefficient compared to former tunings)

3) Throttle/RPM: Improvement of accelerating pump calculation (does not need an adaptation of the accelerating pump coefficient compared to former tunings)

4) Tuning of cut off RPM offset (helpfull for sharp engines)

5) Tuning of tic over throttle position (helfull for going back to move off RPM limiter)

Throttle/RPM : V435

Pressure/RPM : V315

A) CHALLENGER4 ERRORS CORRECTION:

1) On cut off (do not use injection cut off on former versions).

2) On move off RPM limiter (difficult going back to move off limiter on former versions).

3) On intake pressure stabilisation (could generate problems on former versions in case of vacuum instability).

B) NEW CHALLENGER4 FUNCTIONS:

1) continuous display of correct gear on sequential gearboxes (for dashboards).

2) Recording of sensor faults even after ECU switch off.

3) Improvement of calculation speed (+++).

C) DOCUMENTS CORRECTION:

1) Challenger4+ installation document correction (notably on ignition coil modules connections)