New software version Adv88_ENU-2.4.0.0.zip of the ADVANCE88 ECU

SECURE METHOD OF ECU UPGRADE

Here is the simple and secure method of update of your ECU with a new software version.

WARNING LEVEL : NORMAL

NEW FEATURES AND IMPROVEMENTS

Addition of the injection cutoff at gear upshift on sequential gearbox

• The injection cutoff at gear upshift allows to avoid the explosion in the exhaust and so to decrease the noise at gear shifting.

Addition of fuel high pressure protection (direct injection)

• This allows the engine to be stopped when the fuel high pressure drops unintentionally.

• Prevents a lean running that is destructive for the engine.

Addition of gradual ignition cut-off by bang-bang (ALS pop and bang) (V230)

• The gradual cut-off of the ignition by the bang-bang produces a machine-gun bang-bang, with many small explosions in the exhaust.

Securing of the synchronization on the engine flywheel (V220)

• Improvement of the synchronization security at the engine start.

• Resynchronization in case of tooth length exceeding by loss of teeth from the engine speed sensor.

CONTENT

Advance88 Tunewares:

• System V200 (18th 08/2025)

• Throttle/RPM: V240 (new – 29th 12/2025)

• Pressure/RPM and turbo: V240 (new – 29th 12/2025)

Documentations in English:

• Advance88 tuning software pack: 52 separate documents, each for one specific fonction of the ECU, with many didactic examples (new – 29th 12/2025)

• Ethanol complete tuning and Hard cut rpm limiter documents

• Advance88 installation: V1.70 – with commands of ignition modules (new – 9th 12/2024)

• Advance88 options installation: V1.50 – sequential gearboxes, fly by wires, bang-bang, Vanos BWM … (new – 9th 12/2024)

Nota:

• Does not contain Winjall software. Winjall must first be downloaded and installed apart.

• Does not contain the sensors convertion maps nor the actuators command maps. These maps have to be downloaded and installed apart with the pack SensAct.

LAST SECURITY CRITICAL MODIFICATION DONE

Not needed.

NEEDING Winjall V9.9.4.0 (see specific downloading)

V9.9.4.0 or later version of Winjall software must mandatory have been installed first.

HOW TO UPGRADE TUNEWARES

• Download new .zip Advance88 software pack file and save it in a directory on your hard disk.

• If you have already installed a former version of this pack, you have to usinstall it before installing this new one:

In Windows XP, execute ‘Start/Parameters/Configuration/Add-Remove programs’.

In Windows 7 and latter versions, execute ‘Start/Parameters/Configuration/Programs and features’.

In the software list, select Advance88 then ‘Uninstall’. Follow uninstall instructions.

• With the files explorer, double click on the downloaded software pack .zip file, then double click on Setup. At the question on files extraction, answer ‘Extract All’.

• If the installation does not automatically start: in the new directory created by the extraction, double click on Setup (application).

VERSIONS HISTORY

(Improvements are added from a version to the next one)

Throttle/RPM : V230 (System V200)

Pressure/RPM : V230 (System V200)

1) Addition of gradual ignition cut-off by bang-bang (ALS pop and bang)

– The gradual cut-off of the ignition by the bang-bang produces a machine-gun bang-bang, with many small explosions in the exhaust.

2) Improvement of oil pressure protection

– Option of not shut off the engine if the oil pressure measured by the sensor is 0 bar.

Throttle/RPM : V220 (System V200)

Pressure/RPM : V220 (System V200)

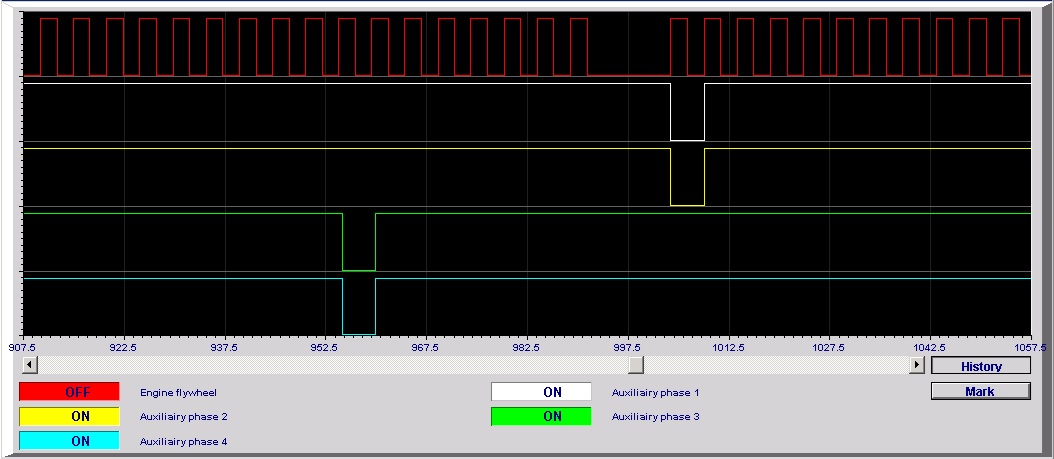

1) Securing of the synchronization on the engine flywheel

– Improvement of the synchronization security at the engine start.

– Resynchronization in case of tooth length exceeding by loss of teeth from the engine speed sensor.

2) Improvement of the variable camshaft management (vvt)

– Better reaction in case of camshaft position measurement error.

3) Improvement of turbo management

– PID Integral reset for overshoot management.

Throttle/RPM : V210 (System V190)

Pressure/RPM : V210 (System V190)

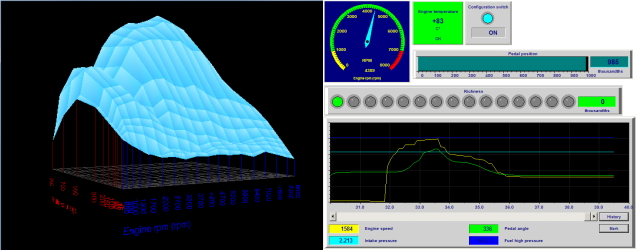

1) Display scope of flywheel and phase teeth.

Allows an easy test of flywheel and phase teeth for engine synchronization.

See new document ‘Advance88 Engine flywheel and phases test – V100’

2) Improvement of the synchronization at engine start

– Strict or normal synchronization selection.

– For motorcycle engines, a coefficient is used to give the allowed reduction of the long tooth when cranking the engine.

3) Improved ignition advance and injection time modification during start procedures

– Selection allowed of the scale variable for the advance and injection time modification maps.

4) Improvement of turbo pressure protection

The ECU can gradually cutoff the cylinders in case of turbo pressure exceeding

5) Addition of the variable valve lift BMW Valvetronic management

Needs our driver RBM03 (ask us if you need it)

Throttle/RPM : V200 (System V180)

Pressure/RPM : V200 (System V180)

1) Improvement of vehicle speed limiter.

Addition of the possibility for the driver to increase or decrease the vehicle speed by the mean of two buttons.

Vehicle speed limiter more efficient: faster reaction and smoother

2) Selection of cylinder 1 TDC for injection phase:

Possibility to phase the injection in relation with the cylinder 1 exhaust TDC or in relation with the compression TDC.

3) Improvement of the possibility of manually modifying the mini-maxi calibration of the motorized throttle:

In case the throttle does not have strong minimum or maximum mechanical stops, the electric motor exceeds the normal min and max positions.

When exceeding the normal maximum opening, the throttle gears are forced and the teeth of the plastic gear wear and destroy over time.

Throttle/RPM : V190 (System V170)

Pressure/RPM : V190 (System V170)

1) Possibility of manually modifying the mini-maxi calibration of motorized throttles.

In case the throttle does not have minimum or maximum mechanical stops, the electric motor exceeds the normal min and max positions.

2) Smooth out jerks during foot lifts and rehitching:

Particularly useful with multi-throttle engines which give significant jolts in these conditions.

3) Management of fuel high pressure pumps by external synchronous pulses:

For example on BMW S55 engines on which the pump turns faster than the crankshaft.

4) Improvement of variable camshaft management:

Correction of the command in function of the engine temperature and engine speed.

5) Data transmission by CAN-Bus to DashBoards:

InjMin configuration (Injall reduced) now passes fuel pressure, oil pressure and oil temperature.

Throttle/RPM : V180 (System V160)

Pressure/RPM : V180 (System V160)

1) Improvement of the balance between cylinders for knock measurement.

2) Securization of engine synchronization in case of phase sensor failure.

Throttle/RPM : V170 (System V150)

Pressure/RPM : V170 (System V150)

1) Memorization of performed engine protections.

2) Improvement of fuel pressure protection.

3) Improvement of twin turbos operation.

4) Improvement of turbos speed correction by Ethanol content.

Throttle/RPM : V160 (System V140)

Pressure/RPM : V160 (System V140)

1) First version able to measure two potentiometer tracks on one main throttle.

Previous versions measure two potentiometer tracks per throttle only for two bank 1 and bank 2 throttles.

2) Complete flex-fuel management with Ethanol content sensor.

3) Machine gun Hard cut RPM limiter with burst of flames.

Throttle/RPM : V150 (System V140)

Pressure/RPM : V150 (System V140)

1) Complete flex-fuel management with Ethanol content sensor.

2) Machine gun Hard cut RPM limiter with burst of flames.

Throttle/RPM : V140 (System V140)

Pressure/RPM : V140 (System V140)

Start version.